Europe’s Metalworking Journey: From Ancient to Industry

Metalworking is the foundation behind Europe’s most iconic medieval swords, Renaissance masterpieces, and modern skyscrapers. Without it, the continent’s progress might have stalled far earlier. Let’s explore how metalworking evolved from a primitive craft into an industrial powerhouse over millennia.

Early Beginnings: Copper and the Bronze Age

Around 3200 BCE, early humans discovered copper tools by striking shiny rocks against one another. Although copper was soft and limited, the advent of the Bronze Age marked a pivotal development as ancient Europeans alloyed copper with tin to create bronze—much tougher and more durable. This breakthrough improved tools and weapons dramatically, fueling complex societies and extensive trade networks across Europe.

The Iron Age: Steeling Europe’s Future

By 700 BCE, iron metallurgy revolutionized Europe. Iron was abundant and, once mastered, allowed the production of stronger, more versatile tools and weapons. Achieving this required advanced smelting techniques and hotter furnaces, heralding a technological leap. Iron’s accessibility democratized metal tools, enhancing agriculture and warfare and expanding Europe’s capabilities.

Roman Metallurgy: Mass Production and Systematization

The Romans elevated metalworking to new heights with large-scale production and standardization. Utilizing bellows-driven blast furnaces, they improved iron quality and established precise weights and measures to maintain consistency. Roman workshops mass-produced metal goods—nails, hinges, pipes— laying the foundation for systematic industrial metalworking.

Medieval Innovations: Mechanization and Guilds

During the Middle Ages, mechanization advanced metalworking significantly. Water-powered bellows and hammers increased furnace temperatures and efficiency. A mining boom supplied raw materials, while guilds organized craftsmen, safeguarding trade secrets and fostering innovation. These developments refined metalworking practices and protected the craft’s integrity.

Renaissance Metalworking: Science Meets Craft

The Renaissance merged scientific inquiry with artisan skill. Metallurgists studied metal properties meticulously, refining techniques to control heating and cooling processes. Master goldsmiths and metalworkers produced intricate works reflecting both technical and artistic excellence. Enhanced trade accelerated the dissemination of these metalworking innovations.

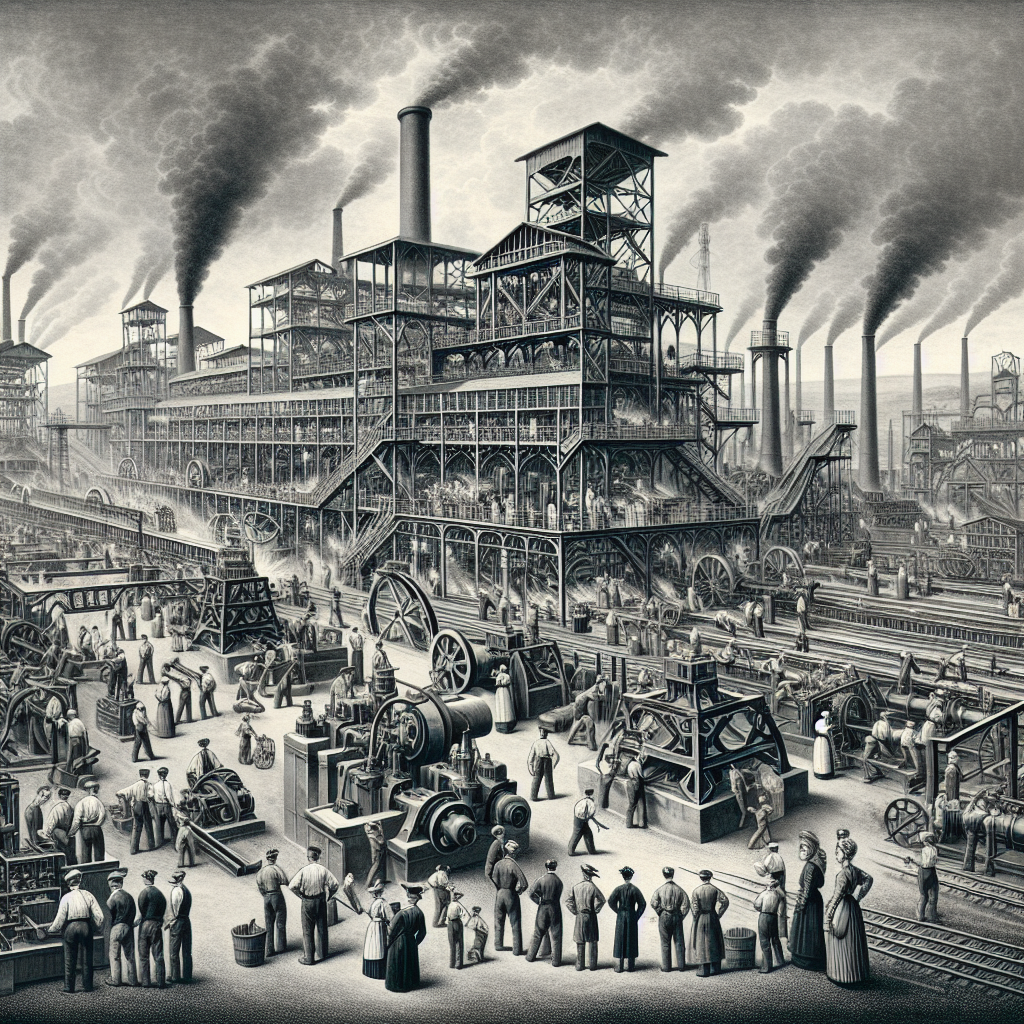

The Birth of Industrial Metalworking: Blast Furnaces and Beyond

From the 15th century onward, blast furnaces enabled mass production of cast iron, dramatically reducing costs and expanding availability. Charcoal remained primary fuel initially, but coal’s gradual introduction enhanced efficiency. Water-powered machinery mechanized operations further, setting the stage for the Industrial Revolution.

The 19th Century and the Steel Revolution

The Bessemer process transformed steel production—making it faster, cheaper, and on an unprecedented scale. Steel rapidly became essential for building railways, bridges, and ships, powering Europe’s industrial expansion. Germany and England emerged as dominant metalworking centers, blending innovation with large-scale manufacturing facilities.

Key Takeaways

- Europe’s metalworking evolved from copper through bronze and iron, enhancing strength and utility.

- Roman industrial techniques foreshadowed modern assembly lines.

- Medieval mechanization and guilds advanced craftsmanship and organization.

- The Renaissance integrated science and art in metalworking.

- Blast furnaces and steam power paved the way for the steel-driven Industrial Revolution.

Next time you admire a historic sword or cross an iron bridge, recognize metalworking as the essential craft shaping Europe’s history and industrial might.