Machining and Metalworking: The Future of Manufacturing

Machining and metalworking may not be your typical Friday night excitement (unless you’re a true enthusiast), but without these essential crafts, no metal product—from your car to your coffee maker’s inner components—would exist. In 2025, machining and metalworking are undergoing a tech-driven transformation, making factories smarter, faster, and greener than ever. Let’s dive into the dynamic world of cutting, shaping, and assembling metal—no warranty on jokes included.

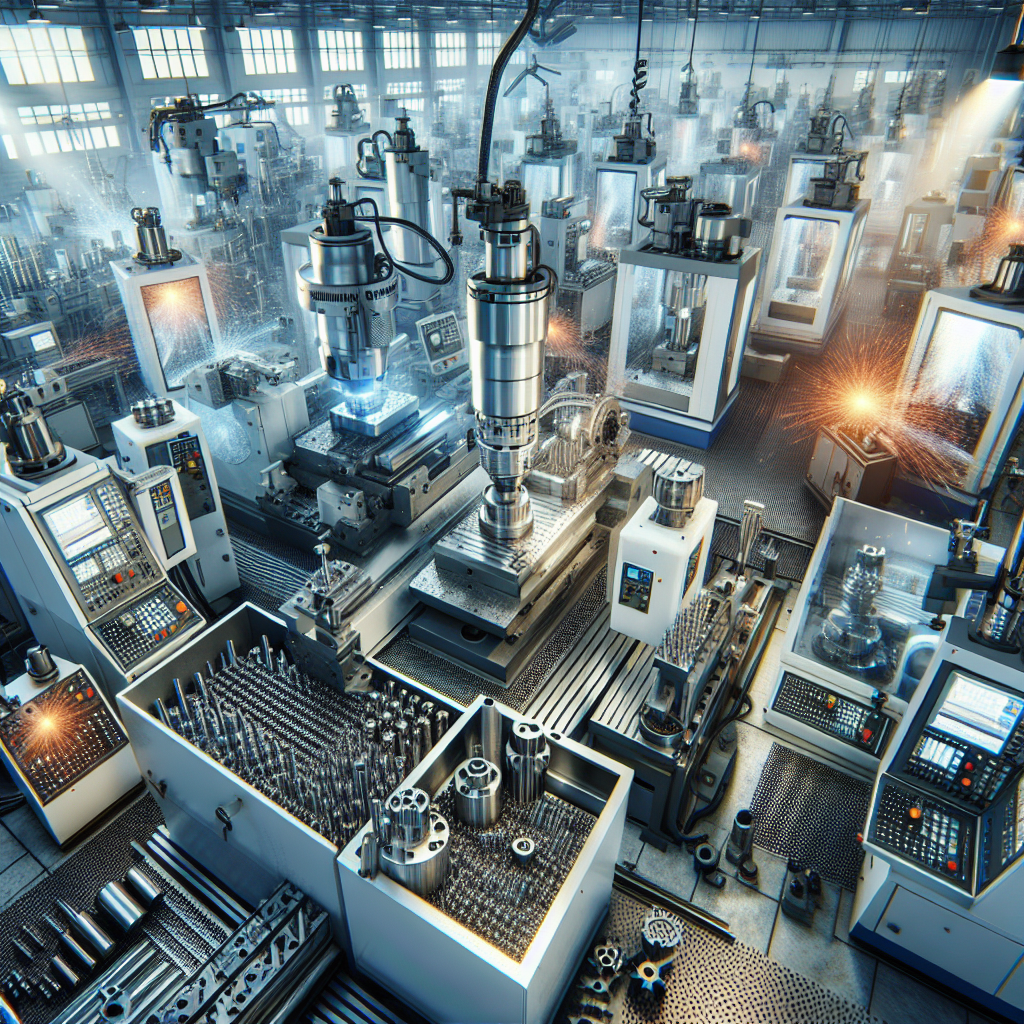

What is Machining in Metalworking?

Machining is the precise art of shaping a solid piece of metal until it fits the exact specifications needed. This isn’t your traditional hammer-and-anvil approach; instead, it involves advanced processes such as:

- Milling: Like using a tiny rotating grater but for metal parts.

- Turning: Spinning metal precisely, as if shaping pizza dough.

- Drilling: Crafting holes in metal with expert accuracy.

- Grinding: Smoothing metal surfaces to a mirror-like finish.

- Electrical Discharge Machining (EDM): Utilizing controlled electric sparks to erode metal delicately.

Machining is fundamental in producing complex aerospace components or the small screws inside your phone, where precision and tight tolerances reign supreme.

The Current State of the Metalworking Industry in 2025

Brace yourself: the metalworking industry in 2025 is booming, with the global metalworking machine market valued at approximately $94 billion. This growth is powered by cutting-edge trends like automation, artificial intelligence, and a new sustainability focus.

Key Trends Elevating Metalworking Today:

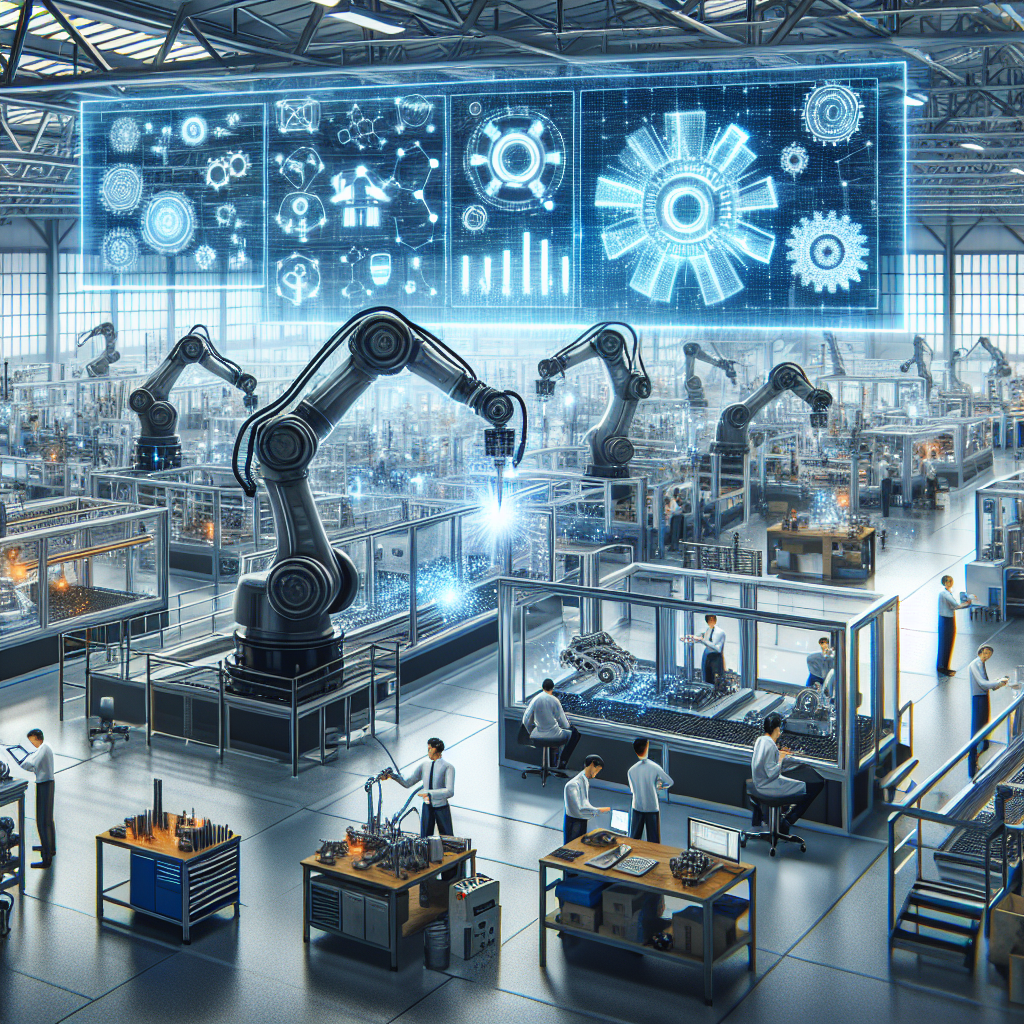

1. Automation and Robotics

Robotic systems are partnering with human operators to boost speed and safety in manufacturing. These robotic arms deliver precise, repeatable movements—like a mechanical ballet crafting your car parts.

2. Advanced CNC Machining

Modern CNC machines integrate AI and IoT technologies, enabling real-time adjustments that achieve exceptional accuracy and repeatability—perfect for meeting demanding production standards.

3. Additive Manufacturing Integration

3D metal printing is revolutionizing production by creating parts layer-by-layer, reducing waste and complementing traditional machining methods for unparalleled efficiency.

4. Sustainability Focus

Metalworking is embracing eco-friendly practices such as recycling metal powders, cutting energy consumption, and minimizing scrap generation to build greener factories.

5. Industry 4.0 and Smart Manufacturing

Connected factories leverage data analytics to monitor equipment health continuously, reducing downtime by quickly addressing issues before they escalate.

Why Machining Metalworking Matters: Real-World Applications

Machining and metalworking are behind countless industries, delivering critical components that keep our world running, including:

- Aerospace: Lightweight, durable jet components.

- Automotive: Precision-engineered engine and chassis parts.

- Medical: Life-saving implants and instruments.

- Energy: Efficient turbines driving power generation.

- Electronics: Durable housings and connectors ensuring device reliability.

By transforming intricate designs into tangible parts, machining plays a pivotal role in modern manufacturing innovation.

Challenges Facing the Machining Metalworking Sector

Despite advancements, the industry faces hurdles like:

- High Capital Costs: Investing in sophisticated machinery requires significant capital.

- Raw Material Price Volatility: Metal costs fluctuate unpredictably.

- Skilled Labor Shortages: The need for trained machinists able to operate complex equipment remains critical.

- Supply Chain Disruptions: Global market uncertainties occasionally impact component availability.

Addressing these challenges means prioritizing smart investments in technology and workforce development.

The Future of Machining Metalworking: What to Expect

Looking ahead, expect exciting developments such as:

- Enhanced AI Integration: Smarter machines collaborating seamlessly with human expertise.

- Hybrid Manufacturing: Combining additive and subtractive processes for optimal production flexibility.

- Sustainable Manufacturing Practices: More energy-efficient, greener factory operations.

- Customized, On-Demand Production: Tailored metal parts manufactured quickly to meet specific needs.

The future of machining and metalworking is agile, sustainable, and innovative—driving manufacturing forward.

In summary, machining and metalworking remain foundational to modern manufacturing. As technology evolves, this vital industry continues to shape our world—both literally and figuratively. Whether you’re a manufacturing professional or simply curious, keep an eye on the cutting edge of metalworking innovations.